1. Primary coating work on wooden door surface. (It will dry for 2-3 days.)

2. Attach shell pieces on thin paper.

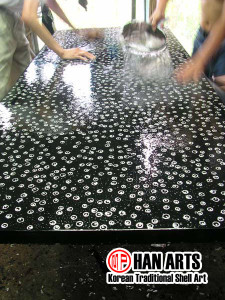

3. Apply glue on the surface of the door where the surface coating is completely dry, and stick thin paper with shell pieces on the door.

4. Use a wet towel to tap the paper so that it sticks well.

5. This is a picture of drying a door with paper pieces (with shell pieces) in the drying room. (2-3 days)

6. Once the shell pieces are fully attached to the door, use warm water to remove the thin paper that is the secondary attachment.

7. Remove the paper and dry the wet door. (3-5 days)

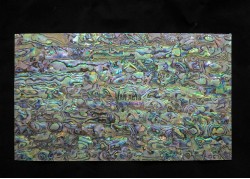

This is just before the last surface coating.

8. Before the last coating (cashew), repair the broken or missing part of the mother-of-pearl.

9. After applying the first coating (cashew), polish it by hand.

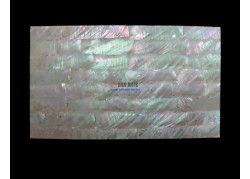

10. Finish work on site to install fully dried door at Lotte Hotel.

11. Pictures of Shell Inlay Door installed at Lotte Hotel.

Seoul LOTTE HOTEL ( 2008 year )

Shell Inlay Door ( Dewdrop design )

Link :

http://shellsheet.com/note/chinese-restaurant-in-seoul-lotte-hotel-sep-2006/