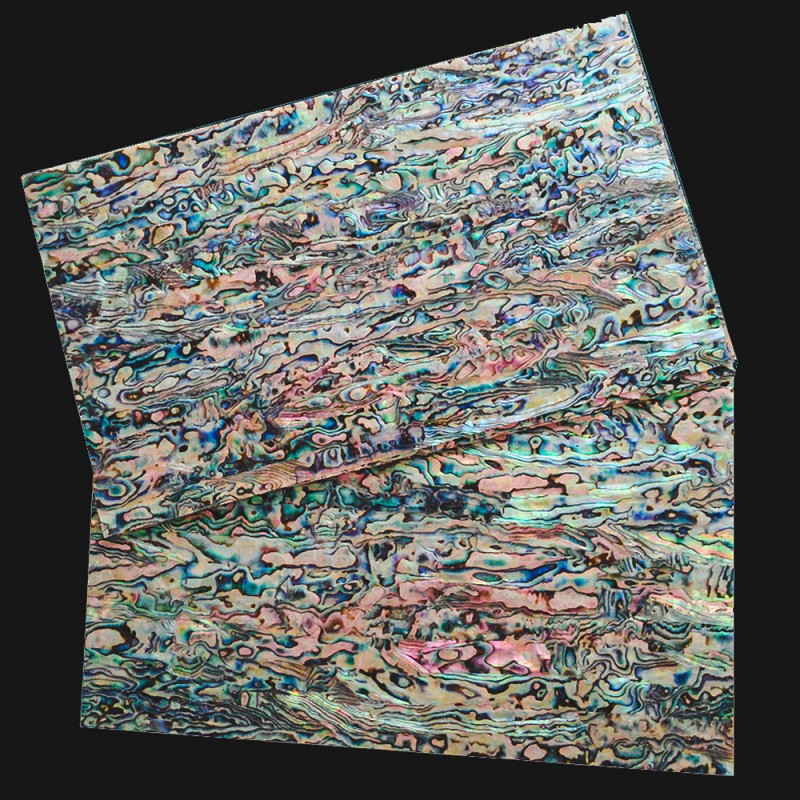

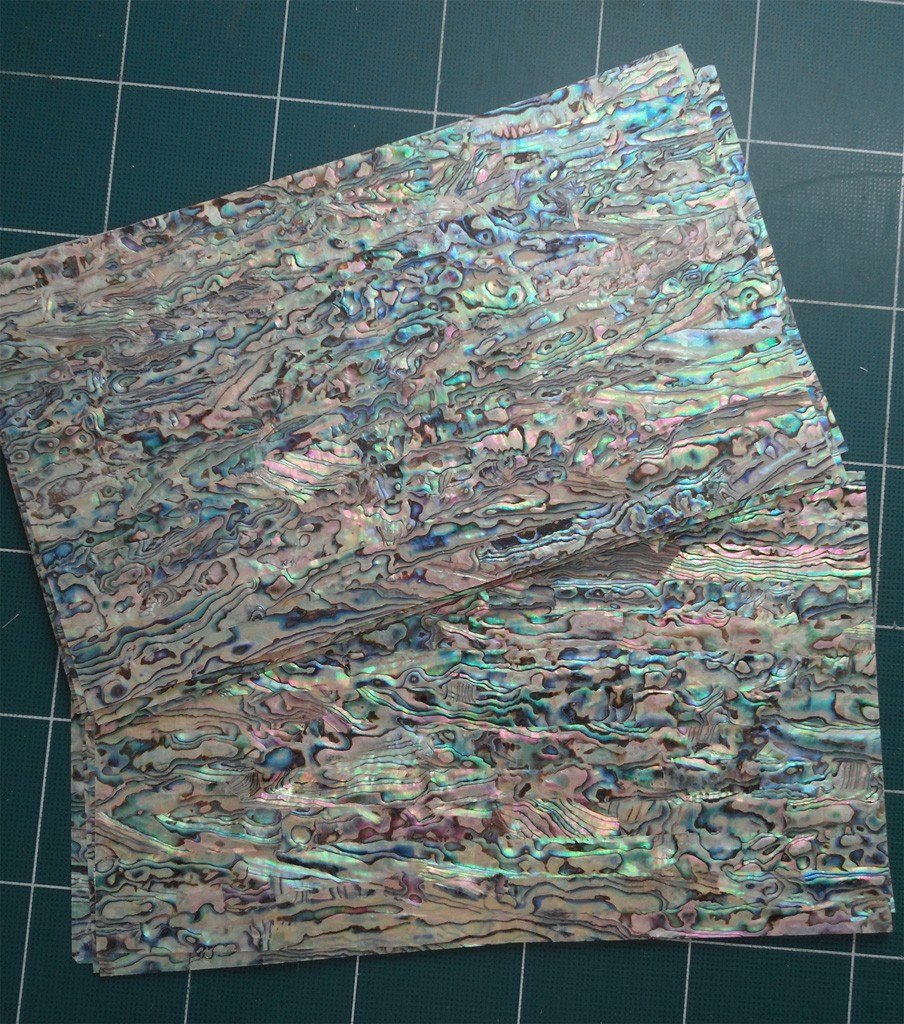

Paua Blue Shell inlay sheet veneer 240 x 140 x 0.15 mm

Paua, known scientifically as Haliotis iris, is a species of abalone native to the coastal waters of New Zealand. Renowned for its vibrant and iridescent shell, paua has been utilized in various decorative applications for centuries. When these shells are meticulously processed into thin sheets measuring approximately 240 x 140 x 0.15 mm, they are commonly referred to as “shell sheets” or “shell veneers.”

Manufacturing Process:

The creation of paua shell veneers involves several intricate steps:

-

Harvesting: Paua shells are sustainably collected from their natural habitats, ensuring ecological balance.

-

Cleaning: The collected shells undergo thorough cleaning to remove any organic material and debris.

-

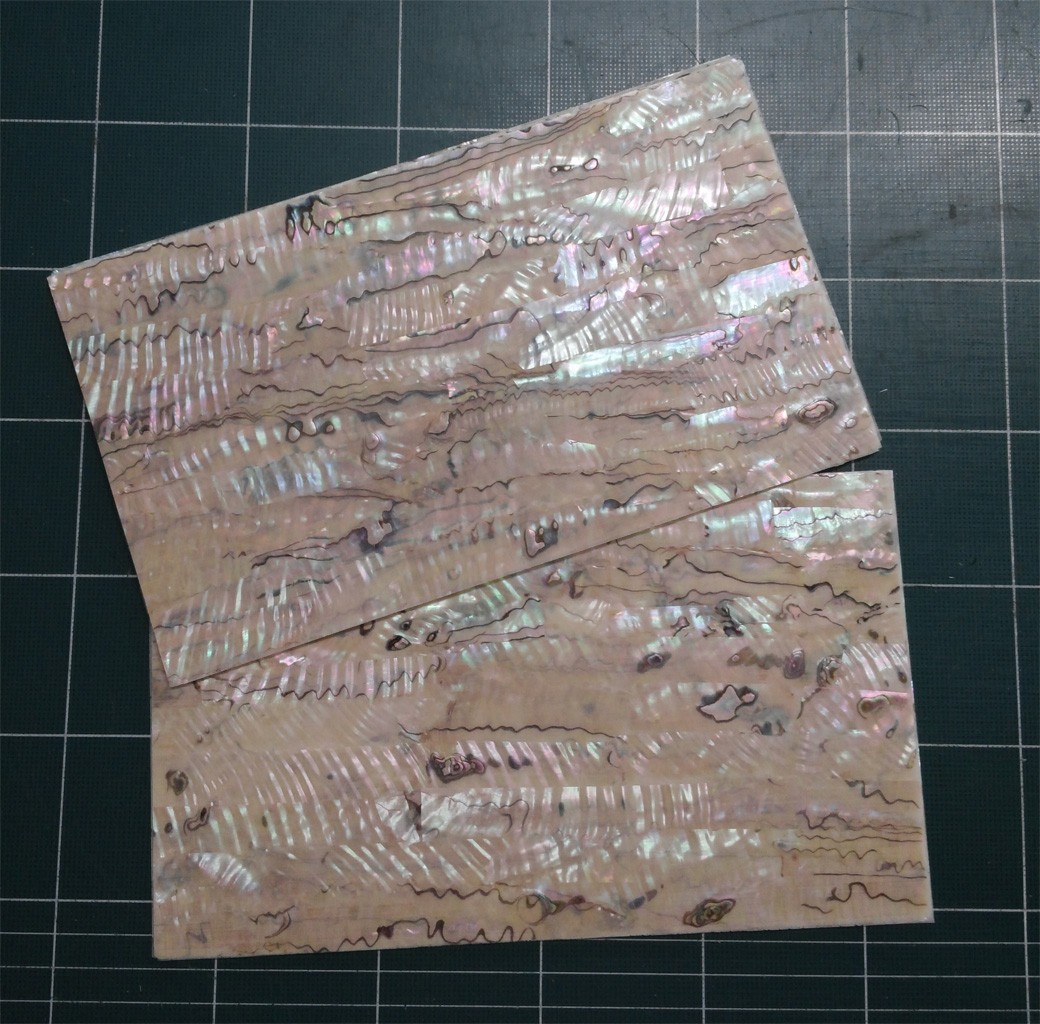

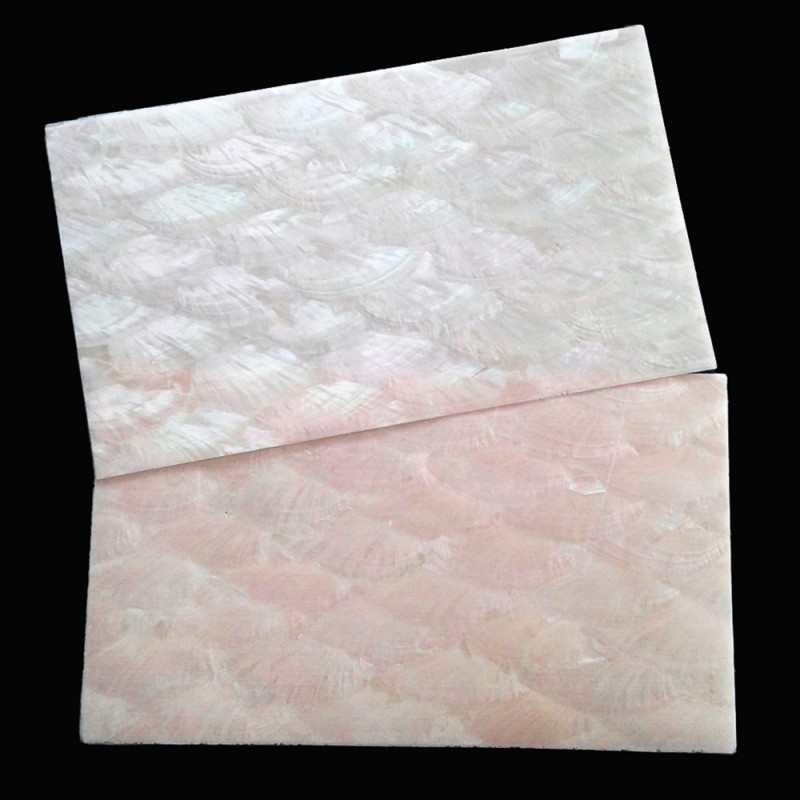

Slicing: The cleaned shells are carefully sliced into thin strips, often referred to as “feathers.” These strips are typically about 1 cm wide and are further sliced into even thinner pieces. This delicate process transforms the curved shell into flat, paper-thin segments.

-

Assembly: The thin shell pieces are meticulously arranged in a tessellating pattern, either in mosaic or strip-like formations, to form a continuous sheet. This arrangement ensures minimal gaps and maximizes the shell’s natural beauty.

-

Bonding: The assembled shell pieces are bonded together using epoxy resin, resulting in a cohesive and flexible sheet. In some cases, multiple layers are laminated to achieve the desired thickness and durability.

-

Finishing: The surface of the veneer is often coated with a clear lacquer or urethane varnish to enhance its gloss and protect it from environmental factors. This coating also deepens the colors, highlighting the shell’s natural iridescence.

Paua Blue Shell Inlay Sheet 240 x 140 x 0.15 mm

Characteristics:

Paua shell veneers are celebrated for their unique aesthetic properties:

-

Iridescence: The natural play of colors, ranging from deep blues and greens to purples and pinks, gives each sheet a distinctive appearance.

-

Flexibility: Despite being made from a hard material, the veneers are thin enough (typically between 0.18 to 0.4 mm) to be flexible, allowing them to conform to various surfaces, including gentle curves.

-

Transparency: The thinness of the sheets allows light to pass through, adding a luminous quality, especially when applied over contrasting backgrounds.

Applications:

The versatility of paua shell veneers makes them suitable for a wide range of decorative applications:

-

Musical Instruments: Luthiers often use these veneers for inlays on guitars, ukuleles, and other instruments, adding a touch of elegance and uniqueness.

-

Jewelry: Artisans craft earrings, pendants, and rings incorporating paua veneers, capitalizing on their vibrant colors and patterns.

-

Furniture: Woodworkers and designers incorporate shell veneers into furniture pieces, such as tabletops and cabinetry, to create striking inlays and surface decorations.

-

Interior Design: Architects and interior designers use these veneers for wall panels, backsplashes, and decorative accents, bringing a natural and luxurious element to spaces.

-

Crafts: Hobbyists employ paua veneers in various DIY projects, including box inlays, decorative trays, and custom signage.

Working with Paua Shell Veneers:

Due to their delicate nature, handling paua shell veneers requires care:

-

Cutting: The veneers can be cut using sharp craft knives, scalpels, or fine-toothed saws. For intricate designs, laser cutters offer precision without causing damage. Applying masking tape over the cutting line can help prevent cracking or chipping.

-

Adhesion: It’s advisable to attach the veneer to a substrate, as the material is too fragile to stand alone. Many veneers come with an optional adhesive backing, such as 3M brand adhesive, which can be applied to the back of the veneer before adhering it to the desired surface. Alternatively, two-part epoxy adhesives are commonly used, especially when bonding to wood or metal surfaces.

-

Finishing: After application, the surface can be sealed with clear lacquers or varnishes to protect the shell and enhance its appearance. It’s essential to avoid abrasive materials or harsh chemicals during cleaning to maintain the veneer’s luster.

In conclusion, paua shell veneers offer a harmonious blend of natural beauty and versatility, making them a cherished material in various artistic and functional applications. Their unique characteristics allow artisans and designers to infuse projects with the captivating allure of the ocean’s depths.